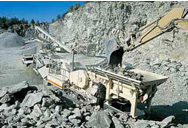

SELECTION OF CRUSHER DESIGN CONCEPTS AS A

2022年4月20日 Husain and Sheikh [3] designed a crusher machine using a scotch yoke mechanism having multi or two-side crushing abilities. Uresh et al. [4] fabricated a compact tin crusher that can be operated manually. Meanwhile, Kumar et al. [5] developed a